Call Us Today

+86-13161061539

Send us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-13 Origin: Site

The 2025 price range for a home food freeze dryer typically falls between $1,000 and $6,000, with most popular models priced from $2,000 to $5,000. Commercial models can cost significantly more. Prices depend on size, features, and brand, as shown in the table below.

Electricity and maintenance create ongoing costs. Each freeze drying cycle typically uses $2–$3 in electricity and requires occasional pump oil changes, which cost about $1 per cycle. These operational expenses add up over time and affect the total cost of ownership.

Operational costs for home models remain manageable. Each cycle uses approximately $2.00 to $2.50 in electricity, with power consumption ranging from 990 to 1,210 watts per hour for small and medium units. Maintenance mainly involves changing the vacuum pump oil every few batches. Most units include an initial oil supply and a filter for reusing oil, which helps reduce ongoing expenses. Manufacturers typically offer warranties from one to three years, and many users report reliable performance for over five years. When stored properly, freeze-dried food can last up to 25 years, making these machines a long-term investment for food preservation.

Commercial food freeze dryer models cater to businesses, large families, and organizations that require higher capacity and advanced features. These units command higher prices due to their size, power, and durability.

Commercial units typically operate at 1,500 watts or more, resulting in higher energy costs per cycle. They require dedicated 20-amp circuits and sometimes higher voltage outlets. Maintenance for commercial freeze dryers involves less frequent oil changes—every 20 to 30 batches—but repairs can be more expensive due to the complexity and scale of the equipment. These machines are built for heavy use, with robust construction and extended warranties. Businesses benefit from the ability to process large quantities of food efficiently, supporting bulk preservation and long-term storage needs.

Tip: Commercial freeze dryers are ideal for food producers, emergency preparedness suppliers, and organizations that need to preserve large volumes of food with maximum shelf life.

The size and capacity of a food freeze dryer play a major role in determining its price and suitability for different users. Larger models can process more food per batch, making them ideal for big families or commercial operations. Smaller units fit well in home kitchens and cost less upfront. The table below shows how size, capacity, and price relate to user needs:

| Model Size | Capacity (lbs per batch) | Price Range | Suitable Users | Highlights |

|---|---|---|---|---|

| Small | ~5 lbs | Lower | Couples, small families | Compact, energy efficient, easy maintenance |

| Medium | ~10 lbs | Moderate | Average families | Balanced cost and capacity, user-friendly |

| Large | Up to 16 lbs | Higher | Gardeners, large families | Durable, efficient, premium features |

| X Large | Over 20 lbs | Highest | Bulk preservation projects | Advanced tech, robust build, highest capacity |

A typical home freeze dryer priced around $2,999 can process up to 18 pounds of food per batch. Larger units cost more but offer greater efficiency for users with high-volume needs.

Advanced features can significantly increase the cost of a food freeze dryer. Automation allows users to monitor and adjust cycles in real time, reducing labor and errors. Digital touch screens make operation simple and user-friendly. Oil-free vacuum pumps lower maintenance needs. Dry time also affects cost—efficient models optimize drying cycles, saving time and energy. Technical specifications like cooling capacity and vacuum pressure further impact price. Brands that offer more automation and user-friendly controls often charge a premium.

Tip: Choosing a model with the right balance of features and automation can save time and reduce long-term costs.

Build quality directly influences both price and longevity. Manufacturers use materials such as stainless steel for vacuum chambers to ensure durability and corrosion resistance. Polycarbonate doors provide visibility and strength, while high-quality silicone gaskets maintain airtight seals. All-metal construction, thick acrylic doors, and reinforced hinges add to the machine’s lifespan and reliability. These robust materials and construction methods justify higher prices by reducing maintenance and extending operational life.

Stainless steel and aluminum components resist wear and support heavy use.

Organized wiring and metal flanges make repairs easier and improve durability.

Energy consumption affects both operational cost and environmental impact. Home freeze dryers typically use 750 to 1,000 watts per cycle, costing between $0.50 and $3.00 per batch. Commercial models use more power, up to 1,500 watts or more. The total energy cost depends on cycle length, food type, and local electricity rates. For example, a medium home unit may consume about 18 kWh in a 24-hour cycle, costing around $3.33 at average rates. Running full loads and pre-freezing food can help optimize energy use and lower costs over time.

A food freeze dryer and a dehydrator use different preservation methods, which leads to distinct results in food quality and storage. The freeze drying process begins by freezing food and then removing moisture through sublimation under a vacuum. This method preserves up to 98% of vitamins and minerals, maintains the original texture, and keeps the flavor intact. Foods processed this way remain crisp and rehydrate quickly. In contrast, dehydrators use controlled heat and airflow to evaporate moisture. This approach changes the food’s texture, often making it chewy or leathery, and causes a greater loss of heat-sensitive nutrients such as vitamin C. Dehydrated foods have a shorter shelf life and may lose some flavor.

| Aspect | Freeze Drying | Dehydrating |

|---|---|---|

| Process | Freezing, then sublimation under vacuum | Controlled heat and airflow |

| Nutrient Retention | Up to 98% of vitamins and minerals | Greater loss of heat-sensitive nutrients |

| Texture | Maintains original, crisp texture | Chewy or leathery |

| Flavor | Preserves original flavor | Often diminished |

| Shelf Life | Up to 25 years | Several months to a year |

Each appliance serves different needs. A food freeze dryer works best for those who want to preserve a wide variety of foods, including fruits, vegetables, meats, and even complete meals, while retaining nutrients and extending shelf life up to 25 years. This makes it ideal for emergency preparedness, long-term storage, and maintaining food quality. Dehydrators are perfect for making snacks like jerky, dried fruits, and herbs. They suit users who want a simple, affordable way to preserve food for short-term use.

Pros and Cons Table

| Appliance | Pros | Cons |

|---|---|---|

| Freeze Dryer | High nutritional retention, long shelf life, better texture and flavor | High cost, higher energy use |

| Dehydrator | Affordable, energy-efficient, easy to use, compact | Greater nutrient loss, shorter shelf life, altered texture |

For users focused on nutrition, shelf life, and food quality, a freeze dryer offers the best results. For those seeking simplicity and affordability, a dehydrator remains a practical choice.

Choosing the right food preservation equipment requires a clear understanding of the differences between freeze dryers and dehydrators, as well as the distinctions among various freeze dryer models. The following table summarizes the most important features, costs, and use cases for each option. This comparison helps buyers quickly identify which machine best fits their needs.

| Feature | Home Freeze Dryer | Commercial Freeze Dryer | Food Dehydrator |

|---|---|---|---|

| Price Range (USD) | $2,000 – $6,000 | $4,000 – $50,000+ | $50 – $500 |

| Batch Capacity | 4 – 18 lbs | 20 – 100+ lbs | 1 – 10 lbs |

| Cycle Time | 20 – 40 hours | 12 – 36 hours | 4 – 12 hours |

| Shelf Life | Up to 25 years | Up to 25 years | 6 months – 1 year |

| Nutrient Retention | 90% – 98% | 90% – 98% | 60% – 80% |

| Energy Use | Moderate | High | Low |

| Maintenance | Oil changes, cleaning | Professional servicing | Minimal |

| Best For | Families, hobbyists | Businesses, large batches | Snacks, short-term storage |

| Warranty | 1 – 3 years | 1 – 5 years | 6 months – 2 years |

Tip: Home freeze dryers offer the best balance for most families. They provide long-term food storage and high nutrient retention without the complexity or cost of commercial units.

Home freeze dryers suit users who want to preserve garden harvests, bulk groceries, or emergency supplies.

Commercial freeze dryers serve food producers, restaurants, and organizations with high-volume needs.

Dehydrators work well for those who want affordable, simple preservation for snacks and everyday use.

Buyers should consider not only the upfront price but also the ongoing costs, maintenance requirements, and intended use. A well-chosen freeze dryer or dehydrator can provide years of reliable food preservation.

Routine maintenance keeps a food freeze dryer running efficiently. Home models require vacuum pump oil changes after every batch or every few batches. Industrial models need oil changes less often, about every 20 to 30 batches. Users should also check and replace door seals, which cost around $60, and monitor sensors or relays, priced between $10 and $20. Vacuum pump oil costs $25 to $40 per gallon, enough for several oil changes. Most refrigeration systems last at least three years, but repairs can cost $300 or more if needed. Advanced models may include features like auto defrost and touchscreen controls, which can affect maintenance complexity.

Home units: oil changes every 1–5 batches

Industrial units: oil changes every 20–30 batches

Door seals: ~$60

Sensors/relays: $10–$20

Refrigeration repairs: $300+

Regular maintenance helps extend the lifespan of any food freeze dryer and ensures consistent performance.

Warranty coverage protects buyers from unexpected repair costs. Most manufacturers offer a full warranty for the first year, covering defects in materials or workmanship. Years two and three usually include limited coverage for sealed refrigeration components, such as the compressor and condenser. Users must follow proper maintenance guidelines to keep the warranty valid. Coverage may vary by region, with some areas requiring the consumer to pay for shipping or service.

| Warranty Period | Coverage Details | Consumer Responsibilities | Impact on Value |

|---|---|---|---|

| Year 1 | Full coverage on dryer and vacuum pump | None for defects; misuse not covered | Ensures initial protection and reliability |

| Years 2–3 | Limited coverage on refrigeration system | Pay for diagnostics and transport | Extends coverage for critical components |

| Exclusions | Misuse, neglect, unauthorized service | Follow maintenance guidelines | Maintains warranty integrity and long-term value |

| Regional | May vary by location | Local service costs may apply | Affects support and value in some regions |

A food freeze dryer comes with several essential accessories, but users often purchase extras for convenience or efficiency. Common accessories include:

Vacuum pump (oil or oil-less)

Stainless steel trays (extra trays for larger batches)

Mylar bags and oxygen absorber packets for storage

Impulse sealer for sealing bags

Silicone mats for easy food removal

Door seals, sensors, and relays for maintenance

Heavy-duty cart for moving the unit

Accessory costs vary. A basic oil pump costs under $200, while an oil-less pump can reach $1,700. Mylar bags and oxygen absorbers are often included, but extra supplies add to the total cost. Door seals cost about $60, and sensors or relays range from $10 to $20.

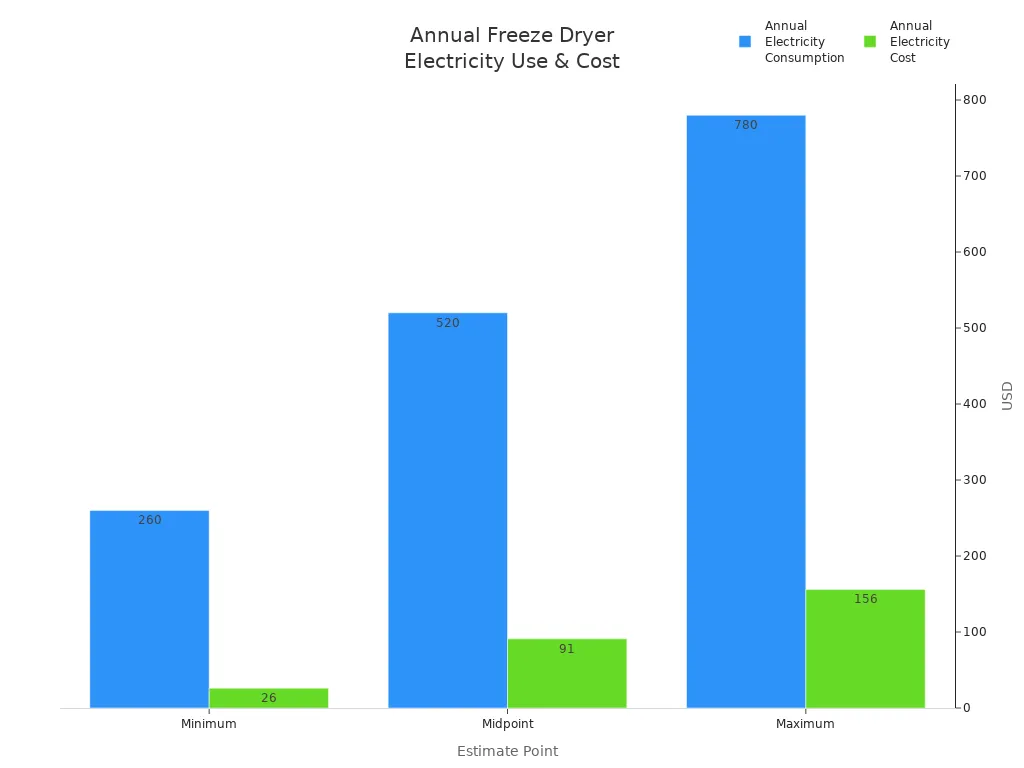

Electricity is a significant ongoing cost for any food freeze dryer. Home units use between 750 and 1,000 watts per cycle, consuming 5 to 15 kWh per batch. At an average rate of $0.18 per kWh, a 24-hour cycle costs about $3.33. Annual electricity use depends on frequency. Weekly operation leads to 260–780 kWh per year, costing $26–$156.

| Freeze Drying Phase | Electricity (kWh) | Cost at $0.18/kWh |

|---|---|---|

| Freeze Cycle | 0.5 | $0.09 |

| Main Drying Cycle | 12 | $2.16 |

| Final Drying Cycle | 6 | $1.08 |

| Total (24 hrs) | 18.5 | $3.33 |

Efficient use and full batches help reduce electricity costs over time.

Selecting the right food freeze dryer depends on several important factors. Buyers should consider their budget, available space, and long-term food preservation goals. A well-matched machine ensures efficient operation and cost-effectiveness.

Budget determines the size and features available. Home models offer affordability, while commercial units require a larger investment but deliver higher capacity.

Space availability matters. Users must ensure the unit fits comfortably in their kitchen or workspace.

Long-term needs guide the choice. Those who plan to preserve large quantities of food may benefit from a larger or commercial model.

Reputable brands with strong customer support and energy-efficient designs help reduce operational costs and improve reliability.

| Factor | Key Considerations |

|---|---|

| Cold Trap Temperature | Lower temperatures improve vapor trapping, important for sensitive foods. |

| Sample Volume | Match unit size to batch size for efficiency. |

| Automation | Programmable cycles and monitoring can save time and reduce labor costs. |

| Maintenance & Support | Easy access to service and parts ensures less downtime. |

| Future-Proofing | Modular and energy-efficient designs support long-term use. |

Home and commercial food freeze dryers differ in cost, size, and features. Home models, priced between $2,500 and $4,500, are compact and designed for personal use. They consume less energy and require less maintenance. Commercial units, ranging from $15,000 to $50,000 or more, offer greater capacity and advanced programmable settings. These machines suit businesses or organizations that need to process large batches regularly. Commercial models require more frequent maintenance, such as vacuum pump oil changes and part replacements, which adds to operational costs. Home units remain user-friendly and cost-effective for families or hobbyists.

Buyers can maximize value by following practical tips:

Choose a machine size that matches food preservation needs to avoid over- or under-investing.

Consider ongoing costs, including electricity, mylar bags, oxygen absorbers, and vacuum pump oil.

Select updated models with stronger pumps and quieter operation for better performance.

Prepare food properly before freeze drying to ensure safety and quality.

Portion food on trays for individual servings, which reduces waste and increases convenience.

Tip: Home freeze drying can save money over time compared to buying commercial freeze-dried foods, even after accounting for supplies and electricity.

A careful approach to selecting a food freeze dryer ensures reliable performance, long-term savings, and high-quality preserved foods.

Food freeze dryer prices in 2025 range from $1,000 for entry-level models to over $50,000 for commercial units. Size, features, and build quality influence cost. Home users often find the best value in mid-range models, while businesses benefit from commercial-grade machines. Buyers should compare capacity, warranty, and ongoing expenses. Careful planning helps users select a food freeze dryer that matches their needs and budget.

Freeze-dried food can last up to 25 years when stored in airtight containers with oxygen absorbers. Proper packaging prevents moisture and light exposure, which helps maintain quality and shelf life.

Fruits, vegetables, meats, dairy, and complete meals perform well in freeze dryers. Foods with high water content, such as berries or mushrooms, retain texture and flavor after freeze drying.

Routine maintenance involves changing vacuum pump oil, cleaning trays, and checking seals. Most users find maintenance straightforward. Manufacturers provide guides and support for troubleshooting common issues.

A typical home freeze dryer uses 750 to 1,000 watts per cycle. Each batch consumes about 5 to 15 kWh, costing $2 to $3 per cycle, depending on local electricity rates.

Yes, freeze dryers can process raw or cooked pet food. The process retains nutrients and extends shelf life, making it suitable for long-term storage of treats and meals.

Beijing Songyuan Huaxing Technology Development Co., Ltd. was founded in 2000, with its headquarters located in Beijing, China.